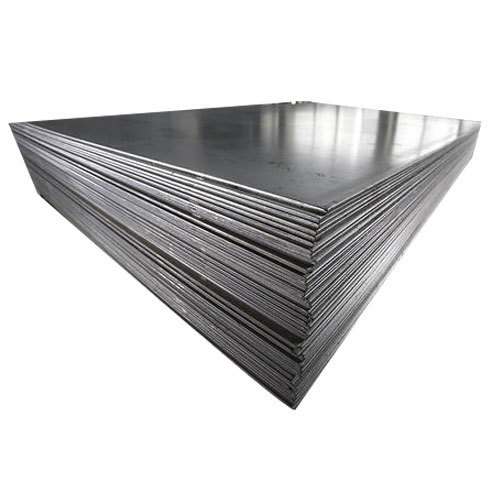

Cold-Rolled steel is produced by rolling process of pickled Hot-Rolled steel to lower thicknesses at low temperature. The Cold-Rolled Steel produced by the Seven Diamonds Industries Company, is a Cold-Rolled low-carbon steel (Reverse mill), processed by batch annealing, skin pass rolling, tension leveling and applying protective oil in order to increase the life of the product. These products are manufactured according to the customer’s request for various applications in accordance with the national and international standards.

Cold-Rolled steel sheet

Description

Cold-Rolled steel is produced by the rolling process of pickled Hot-Rolled steel to lower thicknesses at low temperatures. The Cold-Rolled Steel produced by the Seven Diamonds Industries Company is Cold-Rolled low-carbon steel (Reverse mill), processed by batch annealing, skin pass rolling, tension leveling, and applying protective oil to increase the life of the product. These products are manufactured according to the customer’s request for various applications based on national and international standards.

Cold-Rolled Steel Product

Coil

| General specification of Cold rolled Coil | ||||||

|---|---|---|---|---|---|---|

| width (millimeter) | Thickness (millimeter) | Protective oil ( Grams per square meter) | Inner diameter (millimeter) | |||

| max | min | max | min | max | min | 610 |

| 1280 | 720 | 2.50 | 0.18 | 1 | 0.2 | |

Flat Sheet

| General specifications of Cold rolled flat sheet | ||||||

|---|---|---|---|---|---|---|

| Width (millimeter) | Thickness (millimeter) | Lenght (millimeter) | ||||

| max | min | max | min | max | min | |

| 1280 | 450 | 2.00 | 0.18 | 6000 | 550 | |

Slit Strap

| General properties of Cold rolled Slit Strip | ||||||

|---|---|---|---|---|---|---|

| Width (millimeter) | Thinkness (millimeter) | Weight (Kilogram) | ||||

| max | min | max | min | max | ||

| 1270 | 32 | 2.50 | 0.30 | 19000 | ||

Applications

Standards

| Standard | EN 10130 | JIS 3141 | ASTM 1008 | EN (10139) | INSO(ISIRI) |

|---|---|---|---|---|---|

| Commercial quality | ST12 (DC01) | SPCC | CS(A,B,C).SS25, SS30,SS33 (type1,2), SS40(type1,2) | A,LC.C290,C340 (DC01) A,LC,C290, C390 (DC03)A,C290,C340 (DC04) | 1(5723), 220 250 (5722) |

| Drawing quality | ST13 (DC03) | SPCE | DS(A,B) | LC(DC03) | (INSO 5723) 3 |

| Deep drawing quality | ST14 (DC04) | SPCF | DDS(A,B) | LC(DC04) | (INSO 5723) 4 |

| Non-ageing deep drawing quality | DC05 | SPCG | — | — | — |

| Non-ageing extra deep drawing quality | DC06 | SPCG | — | — | — |

| Structural quality | 1/8Hard | 1/8Hard,1/4Hard | SS 50 | C290,C340, C390,C440 (DC01) C290,C340, C390,C440 (DC03) C290,C340, C390(CD04) | 220, 250, 320 |

| Structural quality | 1/4Hard | 1/4Hard | SS50,SS60 | C340,C390,C440, C490 (DC01) C340, C390,C440(DC03) C340,C390,C440(DC04) | 320 |

| Structural quality | Full Hard | 1/2Hard,Full Hard | SS50,SS60, SS70,SS80 | C340,C390,C440,C490, C590,C690(DC01) C340,C390,C440,C490, C590(DC03) C340,C390,C440, C490,C590(DC04) | 550 |

| Download | EN10130 | JISG3141-2009 | ASTM1008 | EN10139 | inso5723 |